Solar Panel

With certificates: ISO9001 , ISO14001, ISO45001, TUV , UL , CQC etc,

we’ve been continuously provided high-quality solar photovoltaic modules and system solutions

with stronger current capacity and more stable power output,

to ensure that you enjoy the happier life with 100% green energy.

Solar Panel

Solar panel (also known as a PV panel, PhotoVoltaic Panel, solar panel, solar panel, or photovoltaic (PV) module) is a photovoltaic cell assembly installed in a frame to generate energy and is the core part of a solar power generation system. It is also the most important part of the solar power generation system.

Since a single solar cell cannot be directly used as a power source, several single cells must be connected in series or in parallel and tightly packaged into modules if they want to be used as a power source. Its function is to convert the solar energy into electrical energy, and store it in the storage battery, or push the load to work.

The future looks bright for solar energy

Solar photovoltaic power generation will occupy an important seat in the world’s energy consumption in the near future, not only to replace some conventional energy sources, but also to become the main body of the world’s energy supply.

It is estimated that by 2030, renewable energy will account for more than 30% of the total energy structure, and solar photovoltaic power generation will account for more than 13% of the world’s total power supply.

By 2050, renewable energy will account for more than 50% of total energy consumption, and solar photovoltaic power generation will account for more than 25% of total electricity.

By the end of the 21st century, renewable energy will account for more than 80% of the energy structure, and solar power will account for more than 60%.

These figures are enough to show the development prospects of the solar photovoltaic industry and its important strategic position in the energy field.

Advantages & Benefits of Solar Energy

Here are solar energy advantages & benefits:

1) Universal: The sun shines all over the earth, without geographical restrictions. No matter land or sea, no matter mountains or islands, they are everywhere. They can be directly developed and utilized, easy to collect, and do not need to be mined and transported.

(2) Harmless: The development and utilization of solar energy will not pollute the environment. It is one of the cleanest energy sources, which is extremely valuable in today’s increasingly serious environmental pollution.

(3) Huge: The solar radiant energy that reaches the earth’s surface every year is equivalent to about 130 trillion tons of coal, and its total amount is the largest energy source that can be developed in the world today.

(4) Long-term: According to the estimation of the rate of nuclear energy produced by the sun, the storage of hydrogen is enough to last tens of billions of years, and the life of the earth is about billions of years. In this sense, it can be said that the energy of the sun is used Inexhaustible.

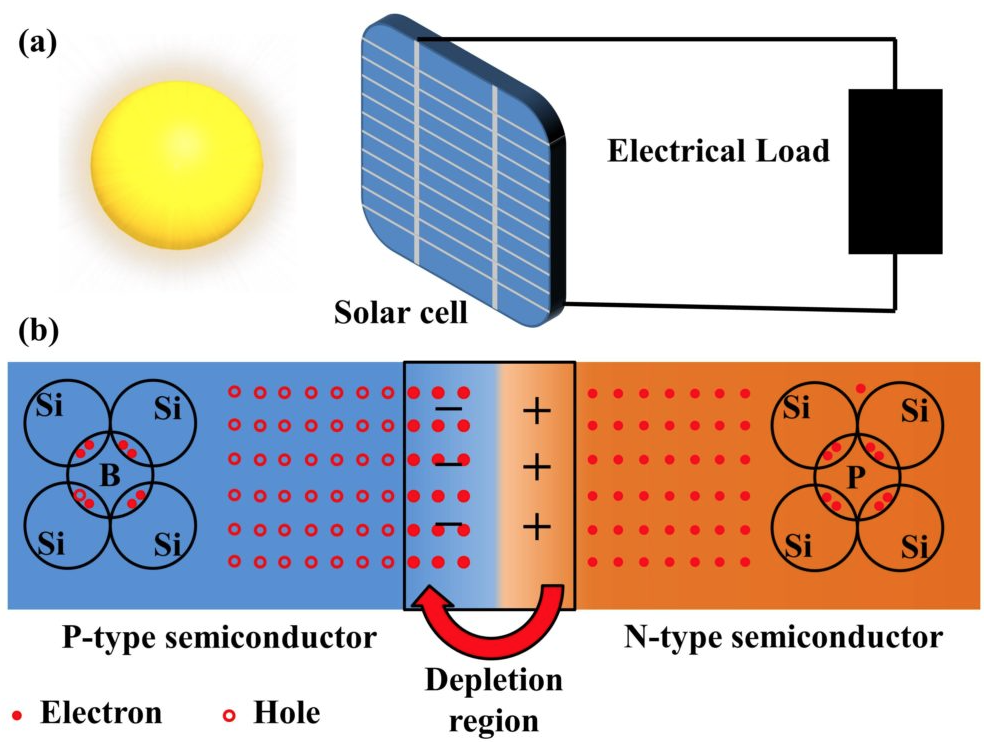

How photovoltaics generate electricity

Solar cells are the carriers that complete the conversion of solar energy into electrical energy, and the photovoltaic effect is the basic principle of photovoltaic power generation.

As early as 1839, the French scientist Becqurel discovered that light could generate a potential difference between different parts of semiconductor materials. This phenomenon was later called the “photovoltaic effect”, or “photovoltaic effect” for short. In 1954, American scientists Chapin and Pearson made a practical monocrystalline silicon solar cell for the first time at Bell Laboratories in the United States, and photovoltaic power generation technology was born.

The basic principle of solar photovoltaic power generation is to use the photovoltaic effect of solar cells to directly convert the sun’s radiant energy into electrical energy. The energy converter of solar photovoltaic power generation is solar cells, also called photovoltaic cells.

A photovoltaic cell is actually a large-area silicon semiconductor device. Positive charges represent silicon atoms, and negative charges represent 4 electrons around the silicon atoms. When boron or phosphorus impurities (elements) are doped into the semiconductor silicon crystal, because there are only 3 electrons around the boron atoms, there are only 3 electrons around the phosphorus atoms. There are 5 electrons, so a crystal structure with holes and a crystal structure with excess electrons will be generated to form a P-type or N-type semiconductor.

Since the P-type semiconductor contains more holes, the N-type semiconductor contains more electrons. When P-type and N-type semiconductors form a special thin layer in the interface region of the two semiconductors, the P-type side of the thin layer is negatively charged, and when combined, the type side is positively charged to form a PN junction .

(a) Conversion of solar energy through solar cells.

(b) A visual depiction of p-n junction and depletion region.

Diagram of electrons being freed by the absorption of solar radiation and captured by a solar cell.

When sunlight shines on the photovoltaic cell, part of the light is reflected, part of the light is absorbed, and part of the light passes through the cell. The absorbed light energy excites the electrons in the bound high-energy state to generate electron-hole pairs. Under the action of the built-in electric field of the PN junction, the electrons and holes move with each other, and the holes in the N region move to the P region. The electrons in the N region move to the N region, causing a large amount of negative charges (electrons) to accumulate on the light-receiving surface of the solar cell, and a large amount of positive charges (holes) to accumulate on the backlight surface of the solar cell.

If a load is connected to both ends of the battery, a current will flow through the load, and when the light keeps shining, a continuous current will flow through the load. A monolithic solar cell is a thin semiconductor PN junction with a rated output voltage of 0.5~0.55V under standard light conditions. In order to obtain a higher output voltage and a larger power capacity, in practical applications, it is often necessary to connect multiple solar cells together to form a battery module, or to use more battery modules to form a photovoltaic array.

solar panel components material

♦(1) Tempered glass: ultra-clear tempered glass, its function is to protect the main body of power generation (solar cells), and the light transmittance must be high, generally more than 91%.

♦(2) Encapsulant EVA (Ethylene Vinyl Acetate): A thermosetting and viscous adhesive film, used to be placed in the middle of laminated glass to bond and fix toughened glass and power generation main body (solar cells).

♦(3) Solar Cells: As the most important part of the whole module, its main function is to generate electricity. The mainstream ones are crystalline silicon solar cells (monocrystalline and polycrystalline silicon) and thin-film solar cells, both of which have their own advantages and disadvantages.

♦(4) Back Sheet: Its function is sealing, insulation, and waterproof. Generally, it is made of TPT, TPE and other materials. It’s aging-resistant. The warranty is 25 years.

♦(5) The junction box: It protects the entire power generation system and acts as a current transfer station. If the components are short-circuited, the junction box automatically disconnects the short-circuited battery string to prevent the entire system from being burned.

♦(6) Silicone seal: It is used to seal the junction between components and aluminum alloy frames, components and junction boxes. Silica gel is commonly used, the process is simple, convenient, easy to operate.

♦(7) Aluminum alloy protective laminates: It plays a certain role in sealing and supporting.

Solar cells material types

The current solar cells are classified by material:

♦Crystalline silicon solar panels: polycrystalline & monocrystalline silicon solar cells

♦Amorphous silicon panels: thin film solar cells (flexible solar cells), organic solar cells

♦Chemical Dye Cells: Dye-Sensitized Solar Cells

Now crystalline silicon is the most important photovoltaic material, with a market share of more than 90%, and it will still be the mainstream material of solar cells for a long period of time in the future.

♦Monocrystalline silicon: It is the earliest solar panel made of high-purity monocrystalline silicon rods (purity requirements: 99.999%) as raw materials and cast. It is the most developed and has a relatively mature process. It is made of about 40 monocrystalline silicon and has the highest conversion rate among all photovoltaic modules.

The photoelectric conversion efficiency is about 18%. Now the world’s highest can reach 26.81%, and The price is also gradually reduced, so the popularity is getting higher and higher.

Because monocrystalline silicon is generally packaged with tempered glass and waterproof resin, it is durable and has a service life of up to 25 years.

♦Function: monocrystalline silicon is not only the main material for solar photovoltaic power generation, but also the raw material for manufacturing semiconductor silicon devices, which are used to make high-power rectifiers, high-power transistors, diodes, switching devices, etc.

♦Appearance: The four corners of monocrystalline silicon photovoltaic cells are arc-shaped and rounded, and the cells are square. The color is dark blue, almost black, and there is no pattern on the surface.

♦Polycrystalline silicon: Polycrystalline silicon cells are also made from silicon, but by melting together fragments of silicon crystals. Because the material is easier to manufacture, the cost is cheaper than monocrystalline silicon solar cells, but its conversion efficiency is around 14-18%, which is much lower than monocrystalline silicon.

♦Function: Polycrystalline silicon is mainly used in semiconductors and solar cells. According to different purity requirements, it is divided into electronic grade and solar grade. Among them, about 55% are used for electronic-grade polycrystalline silicon, and 45% are used for solar-grade polycrystalline silicon. However, with the rapid development of the photovoltaic industry, the growth rate of polycrystalline silicon demand for solar cells is higher than that of semiconductor polycrystalline silicon.

♦Appearance: The polycrystalline silicon photovoltaic cell is also square, but its four corners are not rounded but square. The color is sky blue, but it will show colorful colors under certain light, and it has patterns similar to ice flowers on the surface.

“n-type” vs. “p-type” semiconductor solar cells

Conventional crystalline silicon (c-Si) solar cell is a silicon wafer doped with various chemicals to encourage power production. it can be divided to 2 types by different doped chemicals: P-type & N-type semiconduction solar cells.

P-type semiconductors are also called hole-type semiconductors. Doping a trivalent element (such as boron) into a pure silicon crystal to replace the silicon atom in the crystal lattice forms a P-type semiconductor. In P-type semiconductors, holes are many and free electrons are few, and the conduction mainly depends on holes.

N-type semiconductors are also called electron-type semiconductors. N-type semiconductors are formed by doping pentavalent elements (such as phosphorus or antimony) in pure silicon crystals to replace the silicon atoms in the crystal lattice. In N-type semiconductors, free electrons are many and holes are few, and the conduction mainly depends on free electrons.

The market share of p-type and n-type solar cell designs. Credit: ITRPV

Although the first solar cell invented by Bell Labs in 1954 was n-type, the p-type structure became more dominant due to demand for solar technologies in space. P-type cells proved to be more resistant to space radiation and degradation. Since so much research was thrown into space-related solar technology, it was only natural that p-type cell dominance trickled down to the residential solar market.

But more solar manufacturers are adopting n-type structures because of their additional benefits. For one, since n-type cells use phosphorus instead of boron, they are immune to boron-oxygen defects, which cause decreased efficiency and purity in p-type structures. N-type cells are in turn more efficient and are not affected by light-induced degradation (LID).

The International Technology Roadmap for Photovoltaic (ITRPV) predicts that the market share of p-type mono-c-Si will hold around 30% through 2028, while n-type mono-c-Si will increase to about 28% from barely 5% in 2017. This correlates to the industry demand for more high-efficiency modules, so solar buyers can expect more n-type designs entering the mainstream.

| Cell Type | Silicon Base | Top Silicone Layer | Overall Charged | Popularity | Efficiency | Degradation | Reliability in High Temperature | Cost |

|---|---|---|---|---|---|---|---|---|

| P-type | with Boron (B) | N+ Emitter | Positively Charged | Most Common | Lower | Affected by LID/LeTID | Easy to lower lifetime of cell | Lower |

| N-type | with Phosphorus(P) / Antimony (Sb) | P+ Emitter | Negatively Charged | Future Trends | Higher | Not affected by LID/LeTID | Higher temperature tolerance | Higher |

Solar panels continue to become more efficient, enabling homes and businesses to produce more electricity in a limited space. It is worth noting that a major driver for such innovations in solar energy technology has been the drive for higher efficiency. Increasing cell efficiency in solar panels is one of the key aspects associated with competitive module manufacturing since it directly helps in decreasing the overall cell processing costs.

Solar cells technology trends

Comparison of p-type PERC and n-type TOPCon silicon cell designs.

In 2013, researchers at Germany’s Fraunhofer Institute for Solar Energy Systems presented a method of producing high-efficiency n-type silicon solar cells with a novel tunnel oxide passivated contact (TOPCon) structure. This novel cell design achieved high marks for open-circuit voltage (Voc), fill factor and efficiency thanks to excellent surface passivation and effective carrier transport.

In 2022, the Renewable Energy Test Center (RETC) is closely monitoring a technology trend gaining market traction and acceptance: the rise of next-generation n-type PV cells with passivating contacts. Many industry analysts and material scientists believe emerging n-type PV cell designs are the next logical progression on the PV technology roadmap.

Less than a decade later, TOPCon is the buzziest word in solar. The largest module manufacturers in the world are beginning volume production of PV modules with TOPCon cells.

HJT vs TOPCon Solar Cell

Heterojunction HJT: There is a lot of advantages, and it is expected to become the next-generation mainstream technology

(1) Double-sided power generation improves efficiency. Heterojunction HJT double-sided symmetrical structure, the power generation exceeds the single-sided Solar Cell by 10%+, and the current double-sided rate has reached 95%, which has obvious advantages in power generation gains compared with other process routes.

(2) Low light attenuation + low temperature coefficient, strong stability. The Heterojunction HJT Solar Cell reduces the interface recombination and improves the TCO layer and Ag contact performance through a good coating process. The degradation of HJT Solar Cells is less than 3% in 10 years, and only 8% in 25 years. And the Solar Cell temperature coefficient is small, which can reduce the heat loss caused by sunlight.

It can be prepared under a low temperature environment of <250℃. Compared with traditional PN junctions prepared at a high temperature of 900℃, it is conducive to slicing and Reduce thermal damage to reduce the cost of silicon wafers, which has more advantages and room for improvement in terms of production efficiency and product yield.

(3) The process flow is more simplified, and there is more room for efficiency improvement and cost reduction. Compared with PERC’s 8 processes and TOPCon’s 10 processes, Heterojunction HJT can be completed in only 4 processes.

However, the biggest pain point of HJT is the cost issue. One is the cost of new equipment; the other is the cost of silver paste. If the cost of these two aspects is reduced, it is very likely to become the mainstream of the next generation technology.

Process flows for PERC, TOPCon, HJT and IBC

Half-cell & Full-cell solar Panel

The next technology on that mainstream path is half-cell designs. The ninth edition of the International Technology Roadmap for Photovoltaic (ITRPV) predicts the market share of half cells will grow from 5% in 2018 to nearly 40% in 2028.

The half-cell battery technology generally adopts the laser cutting method to cut the standard specification battery into two identical half-cells along the direction perpendicular to the main grid line of the battery, and then weld them in series.

Half-cell modules have solar cells that are cut in half, which improves the module’s performance and durability. Traditional 60- and 72-cell panels will have 120 and 144 half-cut cells, respectively.

When solar cells are halved, their current is also halved, so resistive losses are lowered and the cells can produce a little more power.

Smaller cells experience reduced mechanical stresses, so there is a decreased opportunity for cracking. Half-cell modules have higher output ratings and are more reliable than traditional panels.

The use of half-cell cells can provide great advantages and improve performance in shaded conditions, which is of great significance for the overall power generation of building photovoltaics that is easily affected by other building obstacles.

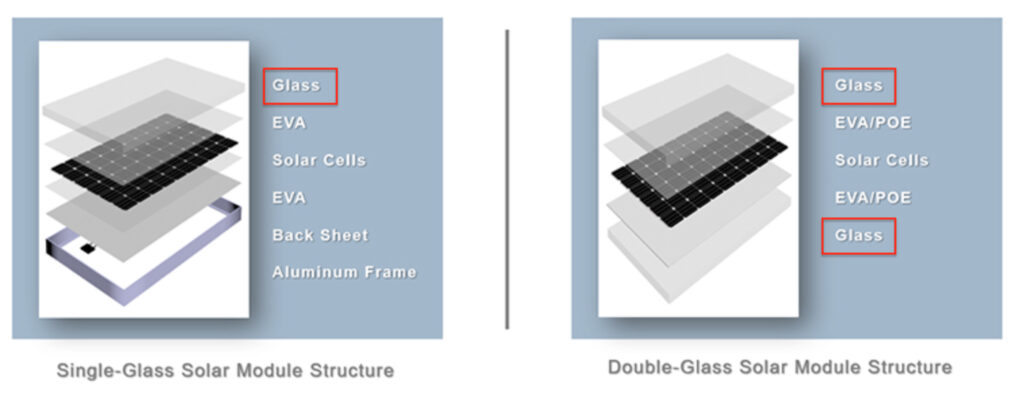

Double-glass & single-glass solar module

Crystalline silicon photovoltaic modules can be divided into double-glass modules and single-glass modules according to the back material.

Compared with single-glass modules, double-glass modules refer to a composite layer composed of two pieces of glass and solar cells, and the cells are connected in parallel by wires to the lead terminals formed by the photovoltaic cell assembly.

Structure Comparison between Double-glass & Single-glass Solar Module

Double-glass Solar Module Structure

In recent years, more and more users will choose double-glass photovoltaic modules when installing photovoltaic power plants. Compared with ordinary single-glass modules, the advantages of double-glass modules are:

(1) The current warranty period for double-glass modules is 30 years, exceeding the 25-year warranty period for single-glass modules.

(2) The power generation of double-glass modules is higher, because the back side of double-glass modules can also generate electricity, increasing the power generation by about 10%-30%.

(3) The wear resistance of the glass is higher than that of the back plate, and the effect is very obvious in desert areas.

(4) The insulation performance of the glass is better than that of the backplane, so that the double-glass module can meet the higher system voltage and save the system cost of the power station.

(5) The attenuation of ordinary components is about 0.7%, and the attenuation of double glass components is about 0.5%.

(6) The fire rating of double-glass modules has been upgraded from Class C to Class A for ordinary modules.

(7) The waterproof rate of the glass is almost zero, regardless of the problem of water vapor entering the component and penetrating the EVA film, especially suitable for seaside water and areas with high temperature.

Recommended solar panel type

According to the current market supply and demand situation, the mainstream monocrystalline silicon photovoltaic modules currently used in large-scale photovoltaic power plants are mainly assembled with 166mm cells and 182mm cells, and photovoltaic modules assembled with 210mm cells also have a certain market share. .

| Cell Size |

Cell Quantity (psc) Full-cell / Half-cell |

Peak Power Output (Wp) |

|---|---|---|

| 166mm |

60/120 ------------ 72/144 |

350-390 Wp -------------------- 420-460 Wp |

| 182mm |

66/132 ------------ 72/144 |

480-500 Wp -------------------- 525-545 Wp |

| 210mm |

50/100 ------------ 55/110 ------------ 60/120 |

480-505 Wp -------------------- 530-555 Wp -------------------- 580-605 Wp |

| Item | Material Type | Cell Type | Back Sheet | Half/full Cell | Cell Size |

|---|---|---|---|---|---|

| Specification |

Polycrystalline silicon solar cells Monocrystalline silicon solar cells |

P-type ( PERC ) N-type ( TOPCon, HJT ) |

Single-glass Dobule-glass |

Half-cell Full-cell |

166mm 182mm 210mm |

| Recommended | Monocrystalline silicon solar cells | N-type ( TOPCon) | Double-glass | Half-cell |

182mm 210mm |

Of course, we can provide the solar panel according to the specification you required.

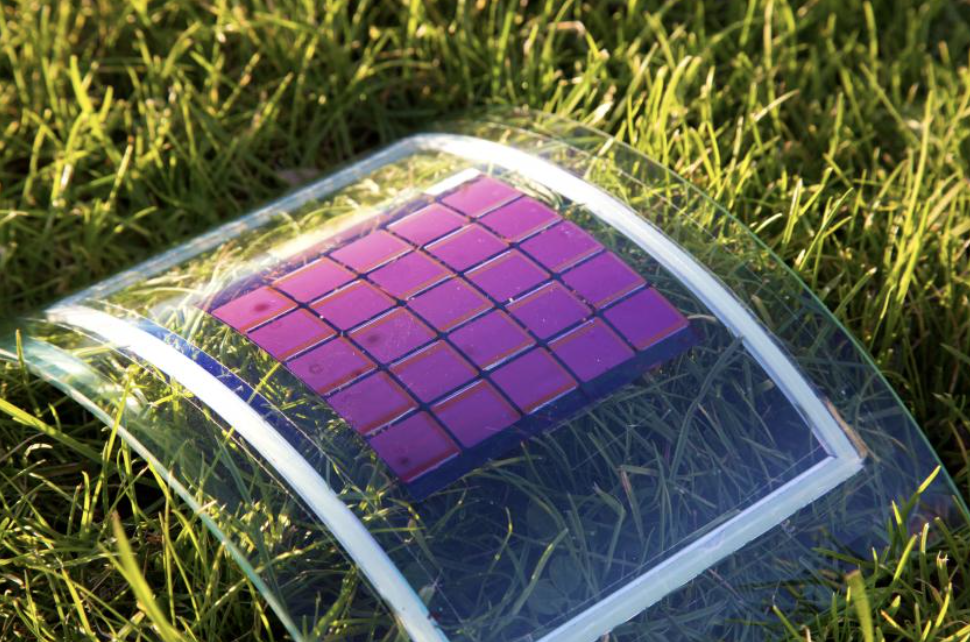

Amorphous silicon solar cell

Thin-film Solar Cells

Thin film solar cells are a very recent development in the solar panel industry. The most outstanding feature of thin film panels is that they are not made of silicon. They can be made from a variety of materials, including cadmium telluride (CdTe), amorphous silicon (a-Si) and copper indium gallium selenide (CIGS).

Compared with crystalline silicon solar panels, their biggest advantage is that they are very flexible and strong, so they don’t need brackets during installation, and they are very convenient to install on roofs and tent tops, and they can also generate electricity under low light conditions. However, its conversion efficiency is only 7-14%, and it is not stable enough. As time goes by, its conversion efficiency decays.

Multi-component compound thin-film solar cells

A multi-component solar cell refers to a solar cell that is not made of a single element semiconductor material. There are many varieties studied in various countries, most of which have not yet been industrialized, and mainly include the following:

♦a) Cadmium sulfide solar cells

The efficiency of cadmium sulfide and cadmium telluride polycrystalline thin film cells is higher than that of amorphous silicon thin film solar cells, the cost is lower than that of single crystal silicon cells, and it is also easy to mass-produce, but because cadmium is highly toxic, it will cause serious damage to the environment. Pollution, therefore, is not the most ideal replacement for crystalline silicon solar cells.

♦b) GaAs solar cells

The conversion efficiency of gallium arsenide (GaAs) III-V compound battery can reach 28%. The GaAs compound material has a very ideal optical band gap and high absorption efficiency. It has strong radiation resistance and is not sensitive to heat. It is suitable for manufacturing High efficiency single junction battery. However, the high price of GaAs materials limits the popularization of GaAs batteries to a large extent.

♦c) Copper Indium Selenium Solar Cell

Copper indium selenium thin film battery (referred to as CIS) is suitable for photoelectric conversion, there is no problem of light-induced degradation, and the conversion efficiency is the same as that of polysilicon. It has the advantages of low price, good performance and simple process, and will become an important direction for the development of solar cells in the future. The only problem is the source of materials. Since indium and selenium are relatively rare elements, the development of this type of battery must be limited.

♦d) New multi-element bandgap gradient Cu(In, Ga)Se2 thin film solar cells)

Cu(In, Ga)Se2 is a kind of solar light absorbing material with excellent performance. It has a gradient energy band gap (the energy level difference between the conduction band and the valence band) and multiple semiconductor materials, which can expand the solar absorption spectrum range, thereby improving photoelectric conversion efficiency. The highest achievable photoelectric conversion rate is 18%.

Moreover, this type of thin-film solar cell has no performance degradation effect (SWE) caused by light radiation, and its photoelectric conversion efficiency is about 50-75% higher than that of commercial thin-film solar panels. The photoelectric conversion efficiency of the world’s highest level among thin-film solar cells.

Dye-sensitized solar cells

Dye-sensitized solar cells (belonging to organic solar cells): Dye-sensitized solar cells are mainly a new type of solar cells developed by imitating the principle of photosynthesis.

Dye-sensitized solar cells use low-cost nano-titanium dioxide and photosensitizing dyes as the main raw materials to simulate the use of solar energy by plants in nature to perform photosynthesis and convert solar energy into electrical energy.

Its main advantages are:

(1) Long life: the service life can reach 15-20 years.

(2) The structure is simple, easy to manufacture, the production process is simple, and it is easy for large-scale industrial production.

(3) The preparation of batteries consumes less energy and the energy recovery cycle is short.

(4) The production cost is relatively low, only 1/5 to 1/10 of that of silicon solar cells, and the cost per peak watt of cells is expected to be within 1.48 US Dollars.

⑸ Non-toxic and pollution-free in the production process;

This new type of solar cell has a wider range of uses than silicon cells: for example, plastic or metal sheets can be used to make it lightweight and thin, various brightly colored dyes can be used to make it colorful. In addition, it can also be designed into various The shape of the solar cell makes it diverse.

In short, the dye-sensitized nanocrystalline solar cell has a very broad prospect of industrialization, and is a new type of solar cell with a wide application prospect. It is believed that in the near future, dye-sensitized solar cells will come into our lives.

Solar energy Uses

Creative Applications of Solar Panel

Solar Home System

Solar Commercial System

Building Integrated Photovoltaic (BIPV)

Solar Telecom Station

Solar Oil Gas Drilling Platform

Solar Power Station

Solar Lighting

Solar Transportation

floating photovoltaic (FPV)

Solar Boat

Solar Farm

Solar Car

Solar Airplane

Solar Satellite

OUR partners

We have worked with TOP10 Solar Panel brands in China.

Get in Touch with us

to start Happier life with Green energy

- One-stop Solution

- Get Step Quote

- 24/7 Service

- Design & Installation Support